Early golf balls were made by stuffing feathers into a leather sack or by molding latex from gutta-percha trees. Most modern balls begin as a block of rubber which forms the solid core.

These peg like pieces are molded into their final round form. Automated equipment puts the core in between the halves of the cover, where it’s brought to a press and molded together.

That’s when the specific dimple pattern of each model is imprinted on the ball. From there, the balls get stamped and painted and are ready for distribution.

More than 850 million golf balls are manufactured each year. That’s nearly one per person for all of North and South America combined.

In this article, we will discuss the production of the golf ball in detail and explain why mounting dimples are critical in its performance and ball flight. Let’s take a look.

How Are Golf Balls Made (Step By Step)

Different types of golf balls deliver different results. Highly skilled golfers often use what’s called a wound ball (a ball made of rubber thread wound tightly over a core) because it’s flight is more controllable.

However, most people use what’s called a 2-piece ball; a ball whose core is covered in a dimpled material.

Today’s golf ball has really come a long way if you consider that the early ones were made of feathers. What’s inside now is a bouncy rubber.

They mix it up with other chemicals to make a hot batter and then roll it out like a pie crust, cooling it between two huge steel drums.

Next they push the rolled up rubbery sheets into a machine called the extruder. There’s a ram inside and it forces the rubber through a die. This makes shapes that resemble large marshmallows called slugs.

A conveyor belt sends them to a compression molding machine.

Here a worker positions two slugs in a steel mold. The slugs often vary in color depending on the type of ball being produced.

When the door closes the bottom part of the mold presses up into the top part, applying over a ton of pressure. This is often referred to as a shape and bake system, because inside the mold, the newly rounded rubber is cooking at 167 degrees celsius.

Mold heats rubber at 167 degrees celsius

Baking it for 13 minutes hardens it. After its cooled with water, a worker places a piece of slotted plexiglass over the mold.

This holds down the leftover trimmings so that only the ball shapes get picked up by the vacuum. The worker then peels off the excess rubber for recycling later.

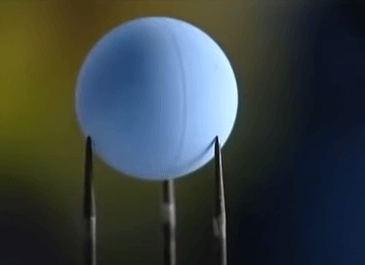

The marshmallow shaped slugs have now been transformed into a solid golf ball core.

Solid golf ball core

A robot transports these cores to another mold. A ram pushes melted plastic through tubes and into a mold cavity. This forms the outside shell of the golf ball, complete with the dimples that will help the ball travel farther.

This is an inside look at a ball with its new shell:

The injection molding system generates four dozen golf balls every minute. The new balls are on the move; they roll into a bin which funnels them to a golf ball elevator. They’re on their way to get cleaned up.

At a closer inspection, you’ll see little pieces of leftover plastic on the ball shells. The next process will get rid of that.

An automatic Miller is used to remove the excess plastic as shown in the gif below:

Here is a golf ball before milling and after the flecks of plastic have been removed:

Next, robotic arms shuttle the golf balls toward a chute entry. This is a quality checkpoint.

If the ball is not smooth and uniform, it won’t go through the hole. Now, a wheel rolls the golf balls towards a stamping machine. Robotic arms carry silicone pads to an etched steel plate.

The pad soaked up ink from the etched plate and transfer it to the balls. The pads brand each ball with a player number the company name and the model type. Then beams of ultraviolet light pardon the ink.

They dump the balls into a bin but they funnel some balls over to another stamping machine that does custom logoing.

Next an automated machine sprays the balls with polyurethane while they rotate atop spindles.

The polyurethane protects the ink logos that have been stamped on the balls. Robotic arms carry the wet golf balls to a drying rack where they cook at 66 degrees Celsius for five minutes. Then they’re done and ready to be delivered to the warehouse.

The Importance Of Molding Dimples On The Surface Of The Golf Ball

When the golf ball is hit, three things happen to it: It gets speed, backspin and an angle of launch.

The backspin is vital to the way the ball goes through the air. The golf ball actually flies through the air, creating a lift as it goes through.

The backspin really helps to do that, and without the dimples none of that would happen as they help to create what is known as ‘turbulence’.

The first time golfers really noticed the effects of dimples was when they were playing with round golf balls. They noticed that after using the balls for such a long time, the surface will get old, beaten and scuffed about which actually helped the ball fly farther.

This is when they came up with the idea of putting something on the surface to make it fly well and that’s when they started molding dimples.

There’s a layer of air very close to the surface of the golf ball and the dimple patterns change the behavior of that layer of air.

The process of that layer of air going from a very orderly laminar-like state to a turbulent state is controlled by the dimples which is critical to controlling the flight of the ball.

Adding dimples actually optimizes flight. Dimples can change the edge angle by half a degree, change depths by a few thousandths of an inch, and change the peak trajectory of a shot by much as six or seven yards.

However, if you start to add a ridiculously large number of dimples, then their size will get smaller. Molding a thousand very small dimples is getting more like a smooth ball.

Therefore, if the dimples become too small, then they won’t have the effect that they’re supposed to have.

On the other hand, if you have too few dimples on the ball, then the dimple size will get larger and that starts to affect the way the ball rolls.

Manufacturers found that anything between 300 and 500 dimples seems to work reasonably well!